Automotive foam inserts, made from advanced materials like PE, PS, and EPP, ensure safe shipping of delicate components by minimizing movement. Custom-fit solutions from Holland, Ohio manufacturers protect intricate items during transit, with precise designs tailored to unique part shapes & sizes. These eco-friendly foam inserts enhance security while reducing waste, making them crucial for the automotive industry's shift towards sustainable practices.

“Revolutionize your automotive packaging with innovative foam inserts—a game-changer in the industry. This comprehensive guide explores the world of custom automotive foam solutions tailored for Ohio’s shipping needs, especially highlighting applications for Holland’s diverse businesses. From understanding the materials and benefits of foam inserts to seeing their success in real-world case studies, this article delves into how these inserts safeguard fragile parts during transit. Additionally, it discusses the growing trend towards eco-friendly practices in automotive packaging.”

- Understanding Automotive Foam Inserts: Materials and Benefits

- Customization in Action: Creating Inserts for Unique Parts

- Shipping with Confidence: Case Studies of Successful Foam Insertion

- Implementing Eco-Friendly Practices: The Future of Automotive Foam Packaging

Understanding Automotive Foam Inserts: Materials and Benefits

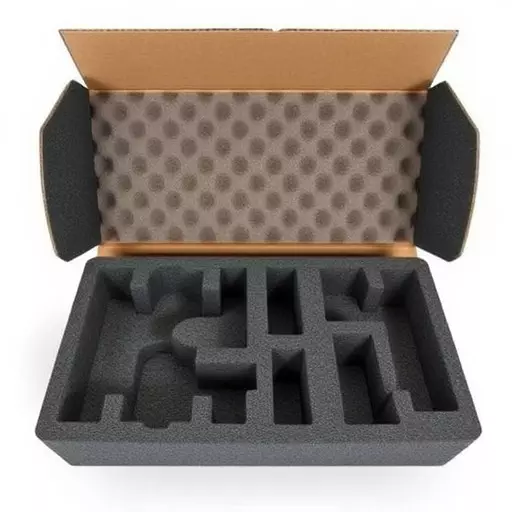

Automotive foam inserts are specialized packaging solutions designed to protect and secure fragile automotive components during shipping and handling. These inserts are crafted using advanced foams that offer unparalleled cushioning and impact absorption, ensuring the safe transit of parts across various environments. The primary materials utilized in their construction include polyethene (PE), polystyrene (PS), and expanded polypropylene (EPP), each known for its unique mechanical properties.

The benefits of automotive foam inserts are manifold. They provide a custom-fit around intricate shapes, preventing movement during transit that could cause damage. This is especially crucial for delicate automotive parts, ensuring they arrive at their destination in pristine condition. Customization options allow manufacturers to tailor the inserts precisely to their specific components, making them ideal for diverse applications in the shipping and handling of fragile automotive items from Holland, Ohio.

Customization in Action: Creating Inserts for Unique Parts

In the world of automotive manufacturing and shipping, every component plays a crucial role in ensuring the safe arrival of vehicles and their intricate parts. Custom automotive foam inserts have emerged as a game-changer in this regard, especially for protecting fragile items during transit. These specialized inserts are designed to fit precisely into specific spaces within vehicles, offering unparalleled customization options. By understanding the unique dimensions and shapes of various automotive parts, manufacturers can create tailored foam solutions that provide optimal shock absorption and cushioning.

For instance, companies based in Holland, Ohio, specializing in automotive foam inserts, can craft custom pieces for shipping delicate components. These inserts are not one-size-fits-all; they are meticulously engineered to accommodate the peculiarities of unique automotive parts. Whether it’s a rare engine part or a specialized interior panel, custom foam inserts ensure that these fragile items arrive at their destination in pristine condition. This level of customization underscores the versatility and importance of foam packaging in modern logistics, especially for industries where precision and protection are paramount.

Shipping with Confidence: Case Studies of Successful Foam Insertion

Shipping with confidence is a cornerstone of any successful business, especially in the automotive industry where protecting delicate components during transit is paramount. Case studies from Holland, Ohio, highlight the transformative power of custom automotive foam inserts in ensuring safe delivery of various parts. These innovative solutions are tailored to fit specific component shapes and sizes, providing a snug, protective environment that minimizes movement inside shipping containers.

By employing advanced materials and precise manufacturing techniques, these custom automotive foam inserts offer unparalleled shock absorption and impact resistance. This is particularly crucial for fragile automotive parts, such as glass components, intricate electronics, and delicate sensors, which require specialized care during transportation. The successful implementation of foam inserts has led to reduced damage rates, faster turnaround times, and enhanced customer satisfaction, solidifying their role as a game-changer in the shipping process.

Implementing Eco-Friendly Practices: The Future of Automotive Foam Packaging

In today’s eco-conscious world, the automotive industry is undergoing a significant shift towards sustainable practices, and this transformation extends to packaging as well. Implementing eco-friendly solutions in automotive foam inserts for shipping is not just a trend but a necessary step towards a greener future. The traditional reliance on petroleum-based foams has raised environmental concerns, prompting manufacturers to explore alternative materials. These innovative approaches aim to reduce the industry’s carbon footprint without compromising product protection during transit.

Custom automotive foam inserts play a pivotal role in this transition. By designing specialized packaging for fragile automotive parts, manufacturers can ensure secure transportation while minimizing waste. This tailored approach not only reduces environmental impact but also provides enhanced protection, addressing the dual needs of sustainability and product integrity. With a focus on innovation, companies in Holland, Ohio, are leading the way by offering advanced foam solutions that cater to both aesthetic appeal and ecological responsibility.